Archive for the ‘3D printing’ category: Page 60

Aug 5, 2019

3D bioprinting breakthrough leads to full-scale, functioning heart parts

Posted by Genevieve Klien in categories: 3D printing, bioprinting, biotech/medical

While in its early stages, bioprinting of human tissue is an emerging technology that is opening up some exciting possibilities, including the potential to one day 3D print entire human organs. This scientific objective has now grown a little bit closer, with researchers at Carnegie Mellon University reporting a breakthrough that enabled the printing of full-scale heart components that in some cases functioned similarly to the real thing.

Aug 2, 2019

3D printing the human heart

Posted by Paul Battista in categories: 3D printing, bioengineering, bioprinting, biotech/medical

Over 4000 patients in the United States alone are waiting for a heart transplant, while millions of others worldwide need hearts but are ineligible for the waitlist. The need for replacement organs is immense, and new approaches are needed to engineer artificial organs that are capable of repairing, supplementing, or replacing long-term organ function.

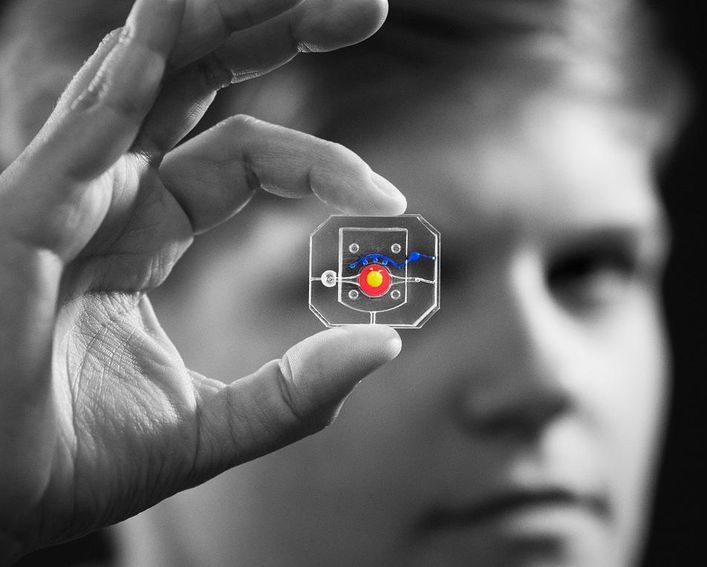

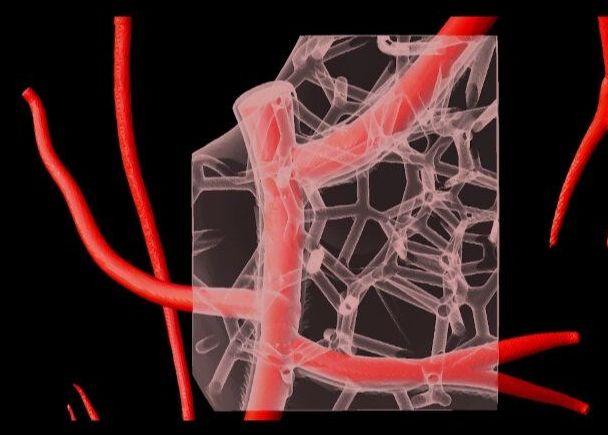

A team of researchers from Carnegie Mellon University has published a paper in Science that details a new technique allowing anyone to 3D bioprint tissue scaffolds out of collagen, the major structural protein in the human body. This first-of-its-kind method brings the field of tissue engineering one step closer to being able to 3D print a full-sized, adult human heart.

The technique, known as Freeform Reversible Embedding of Suspended Hydrogels (FRESH), has allowed the researchers to overcome many challenges associated with existing 3D bioprinting methods, and to achieve unprecedented resolution and fidelity using soft and living materials.

Aug 1, 2019

MIT’s Dr. Robert Langer — The “Edison of Medicine” — ideaXme Show — Ira Pastor

Posted by Ira S. Pastor in categories: 3D printing, aging, bioengineering, biotech/medical, business, disruptive technology, DNA, futurism, health, life extension

Jul 31, 2019

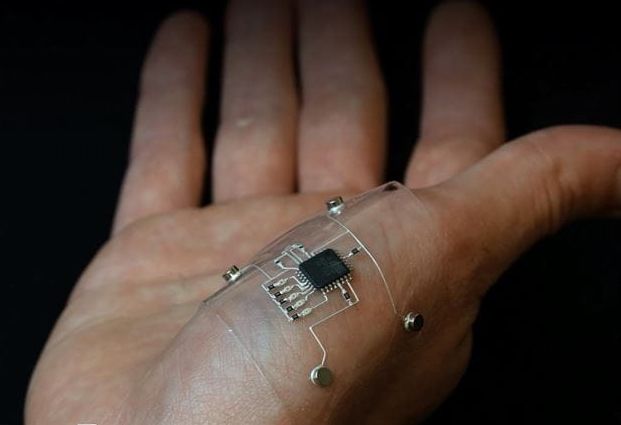

A technique called Hybrid 3D Printing

Posted by Richard Christophr Saragoza in categories: 3D printing, materials

A technique called Hybrid 3D Printing, developed by AFRL researchers in collaboration with the Wyss Institute at Harvard University, uses additive manufacturing to integrate soft, conductive inks with material substrates to create stretchable electronic devices. A potential application is to create sensors to enable better human performance monitoring. (Courtesy photo/Harvard Wyss Institute)

https://www.wpafb.af.mil/…/afrl-harvard-researchers-invent…/

¬

Jul 28, 2019

A 3D-Printable Mecanum Wheeled Robot Platform

Posted by Genevieve Klien in categories: 3D printing, robotics/AI

If your interest lies with robotics there are a multitude of different platforms for you to build. [Teemu Laurila] was frustrated with what was on offer, so designed his own with four-wheel double wishbone suspension and mecanum wheels for maximum flexibility.

It’s a design that has been through multiple revisions since its first iteration in 2015, and along the way it’s clear some thought has gone into it. That double wishbone suspension features an angle for a high ground clearance, and is fully sprung. Drive comes from small motor/gearboxes at each axle. The chassis meanwhile has plenty of space for a single-board computer, and has been specifically designed with the BeagleBone Black in mind.

This build isn’t fully DIY, as the mecanum wheels appear to be off-the-shelf items, but the rest of the project makes up for this. If you need to make your own, it’s hardly as though there aren’t any projects from which you can borrow components.

Jul 25, 2019

A “Cure” for Baldness Could Be Around the Corner

Posted by Quinn Sena in categories: 3D printing, biotech/medical

New uses of stem cells and 3D printing could make baldness obsolete (for the wealthy). James Hamblin 12:51 PM ET.

Jul 23, 2019

SpaceX Falcon 9 rocket to launch 3D printer that could one day print human organs from space

Posted by Alberto Lao in categories: 3D printing, biotech/medical, space travel

For Kenneth Church, sending a 3D printer that could one day print viable human organs to the International Space Station was a personal decision.

Church’s daughter, Kendie Hope, suffered from a diaphragmatic hernia when she was little that prevented her right lung from growing.

“It turned out that my kid shouldn’t have lived,” Church, who is the CEO of nScrypt — an Orlando-based manufacturer that sells 3D printing equipment, said.

Jul 18, 2019

Tiny vibration-powered robots the size of the world’s smallest ant

Posted by Quinn Sena in categories: 3D printing, biotech/medical, robotics/AI

Researchers have created a new type of tiny 3D-printed robot that moves by harnessing vibration from piezoelectric actuators, ultrasound sources or even tiny speakers. Swarms of these “micro-bristle-bots” might work together to sense environmental changes, move materials—or perhaps one day repair injuries inside the human body.

The prototype robots respond to different vibration frequencies depending on their configurations, allowing researchers to control individual bots by adjusting the vibration. Approximately two millimeters long—about the size of the world’s smallest ant—the bots can cover four times their own length in a second despite the physical limitations of their small size.

Continue reading “Tiny vibration-powered robots the size of the world’s smallest ant” »