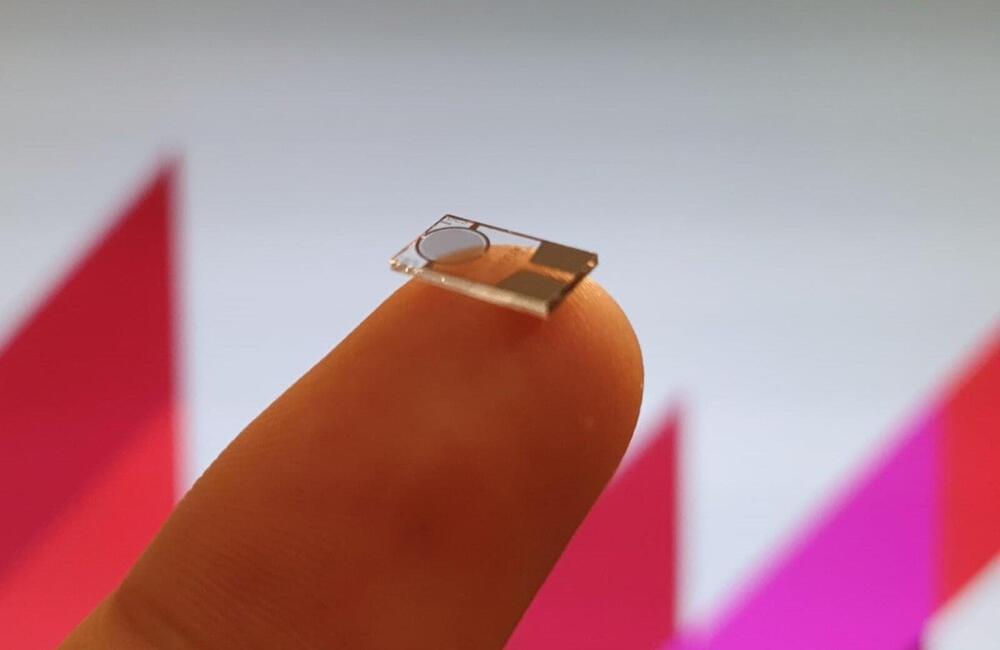

Macquarie University engineers have developed a new technique to make the manufacture of nanosensors far less carbon-intensive, much cheaper, more efficient, and more versatile, substantially improving a key process in this trillion-dollar global industry.

The team has found a way to treat each sensor using a single drop of ethanol instead of the conventional process that involves heating materials to high temperatures.

Their research, published in Advanced Functional Materials, is titled, ‘Capillary-driven self-assembled microclusters for highly performing UV detectors.’

Comments are closed.