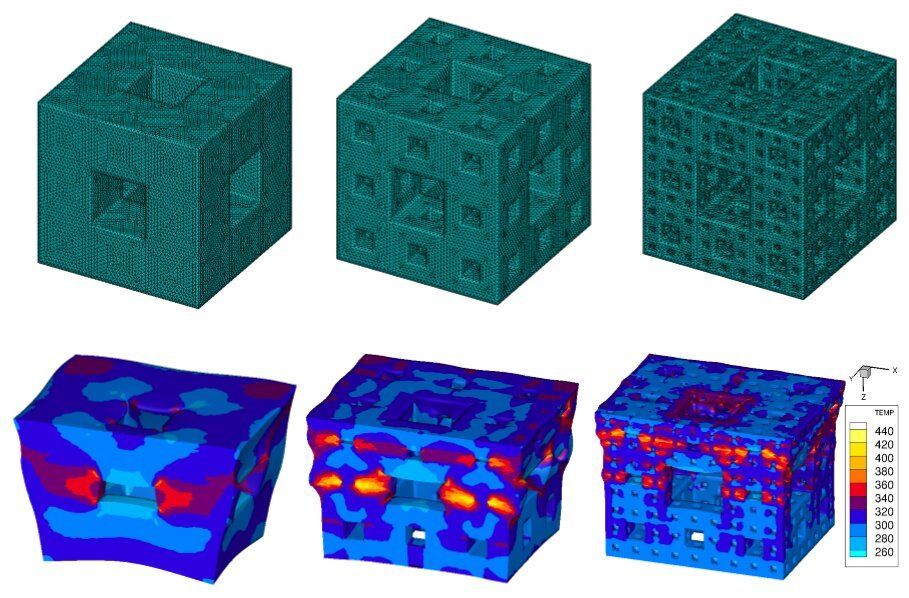

Tiny, 3D printed cubes of plastic, with intricate fractal voids built into them, have proven to be effective at dissipating shockwaves, potentially leading to new types of lightweight armor and structural materials effective against explosions and impacts.

“The goal of the work is to manipulate the wave interactions resulting from a shockwave,” said Dana Dattelbaum, a scientist at Los Alamos National Laboratory and lead author on a paper to appear in the journal AIP Advances. “The guiding principles for how to do so have not been well defined, certainly less so compared to mechanical deformation of additively manufactured materials. We’re defining those principles, due to advanced, mesoscale manufacturing and design.”

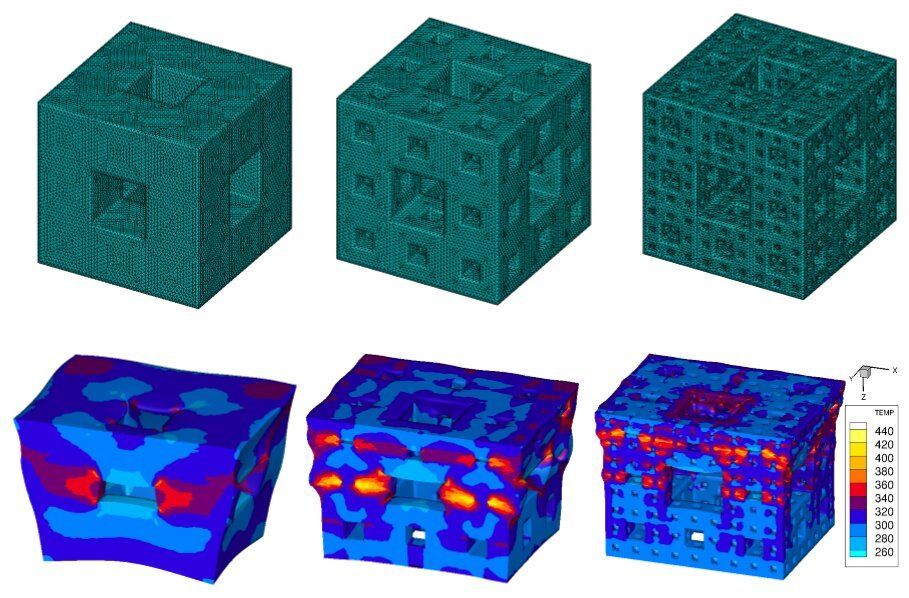

Shockwave dispersing materials that take advantage of voids have been developed in the past, but they typically involved random distributions discovered through trial and error. Others have used layers to reverberate shock and release waves. Precisely controlling the location of holes in a material allows the researchers to design, model and test structures that perform as designed, in a reproducible way.