Aug 11, 2021

Could We Explore the Entire Galaxy With Self-Replicating Robots?

Posted by Quinn Sena in categories: 3D printing, environmental, nuclear energy, physics, robotics/AI, solar power, space, sustainability

Circa 2016

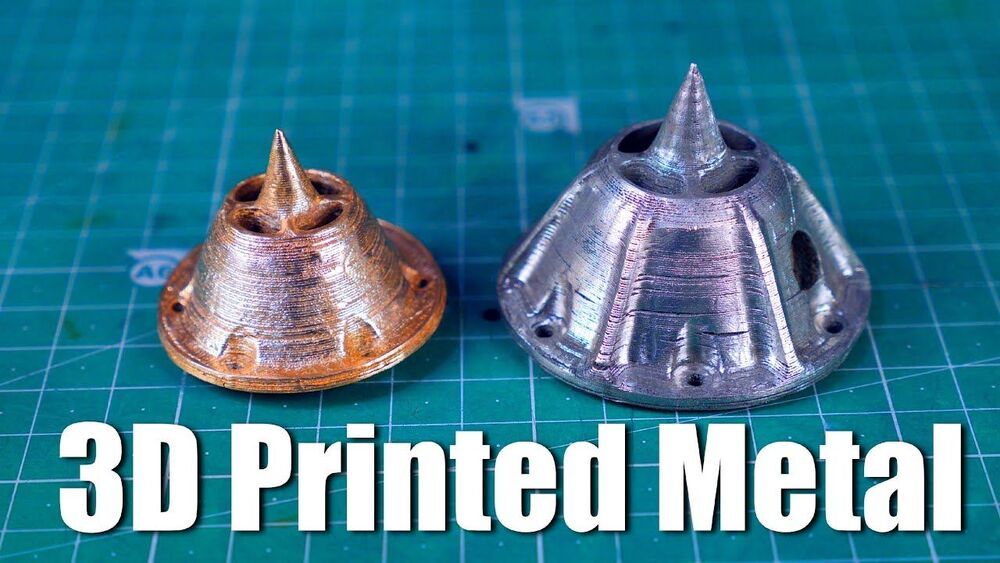

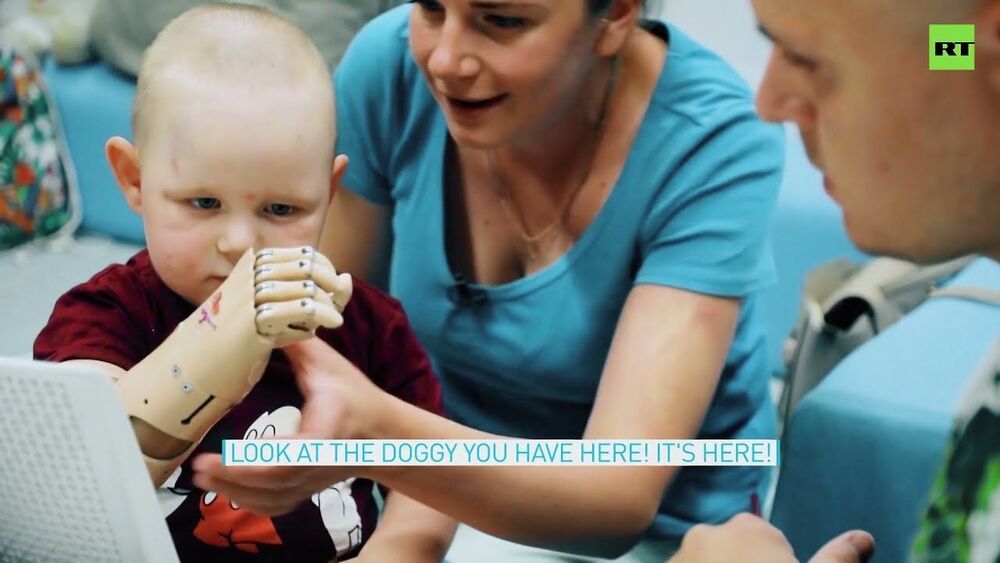

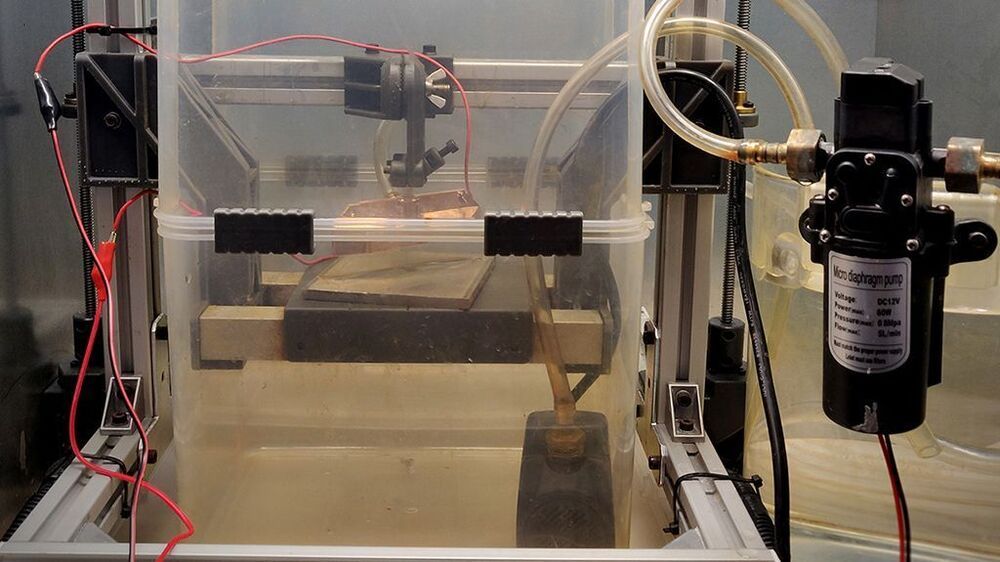

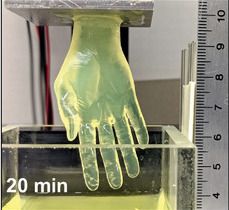

Scientists and engineers since the 1940s have been toying with the idea of building self-replicating machines, or von Neumann machines, named for John von Neumann. With recent advances in 3D printing (including in zero gravity) and machine learning AI, it seems like self-replicating machines are much more feasible today. In the 21st century, a tantalizing possibility for this technology has emerged: sending a space probe out to a different star system, having it mine resources to make a copy of itself, and then launching that one to yet another star system, and on and on and on.

As a wild new episode of PBS’s YouTube series Space Time suggests, if we could send a von Neumann probe to another star system—likely Alpha Centauri, the closest to us at about 4.4 light years away—then that autonomous spaceship could land on a rocky planet, asteroid, or moon and start building a factory. (Of course, it’d probably need a nuclear fusion drive, something we still need to develop.)

Continue reading “Could We Explore the Entire Galaxy With Self-Replicating Robots?” »