Archive for the ‘3D printing’ category: Page 106

Aug 11, 2016

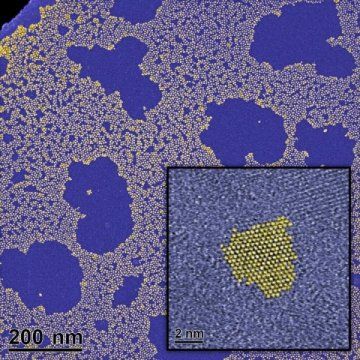

Quantum dots with impermeable shell used as a powerful tool for “nano-engineering”

Posted by Karen Hurst in categories: 3D printing, chemistry, engineering, nanotechnology, quantum physics, wearables

I never get tired of talking about the many uses for Q-dot technology. One area that has me even more intrigued is how it is used in crystallized formations. I expect to see more and more experimenting on crystalized formations on many fronts including complex circuitry for performance and storage.

And, with synthetic technology today plus 3D printing along with Q-dots we could (as I have eluded to many times over several months) truly begin to see some amazing technology be developed on the wearable tech front.

Wearables could include synthetic circuitry stones in various accessories to not only store information, but also serve as another form of unique id because in synthetic stones we have been able (like in nature) create complex crystalized formations that are each unique/ 1 of a kind like a unique finger print, or iris of an eye. I expect to see some very interesting things coming in this space.

Aug 7, 2016

Five New Ideas to be Explored by NASA Aeronautics Teams

Posted by Klaus Baldauf in categories: 3D printing, energy, transportation

They might not work, but no one will know for sure unless they’re given a chance.

That’s the general idea behind the recent selection of five aviation-related technologies for vigorous study as part of NASA’s ongoing Convergent Aeronautics Solutions project during the next two years of so, which itself is now in its second year.

Researchers will study a new kind of fuel cell, increasing electric motor output with the help of 3D printing, use of Lithium-Air batteries to store energy, new mechanisms for changing the shape of a wing in flight and basing a new antenna design on the use of lightweight aerogel.

Continue reading “Five New Ideas to be Explored by NASA Aeronautics Teams” »

Aug 5, 2016

Facebook Live: Deus Ex 3D Printed Bionic Arm

Posted by Shailesh Prasad in categories: 3D printing, biotech/medical, cyborgs, transhumanism

Open Bionics prosthetic arm.

We’re live with Open Bionics and we’re checking out their insanely cool Deus Ex prosthetic arm.

Aug 3, 2016

Saudis look to Chinese 3D printing company to tackle housing shortage

Posted by Karen Hurst in categories: 3D printing, government, habitats

China’s big win.

Last week a team from Chinese 3D printing construction company WinSun visited Saudi Arabia, meeting with department of housing official and others to discuss the kingdom’s housing shortfall.

According to 3ders.com and others, the Chinese firm’s chairman and vice president met officials from the housing department and investment authority, and were told the Saudi government believes WinSun’s technology could help meet a shortage in available housing. WinSun was invited to open a Saudi factory.

Continue reading “Saudis look to Chinese 3D printing company to tackle housing shortage” »

Aug 3, 2016

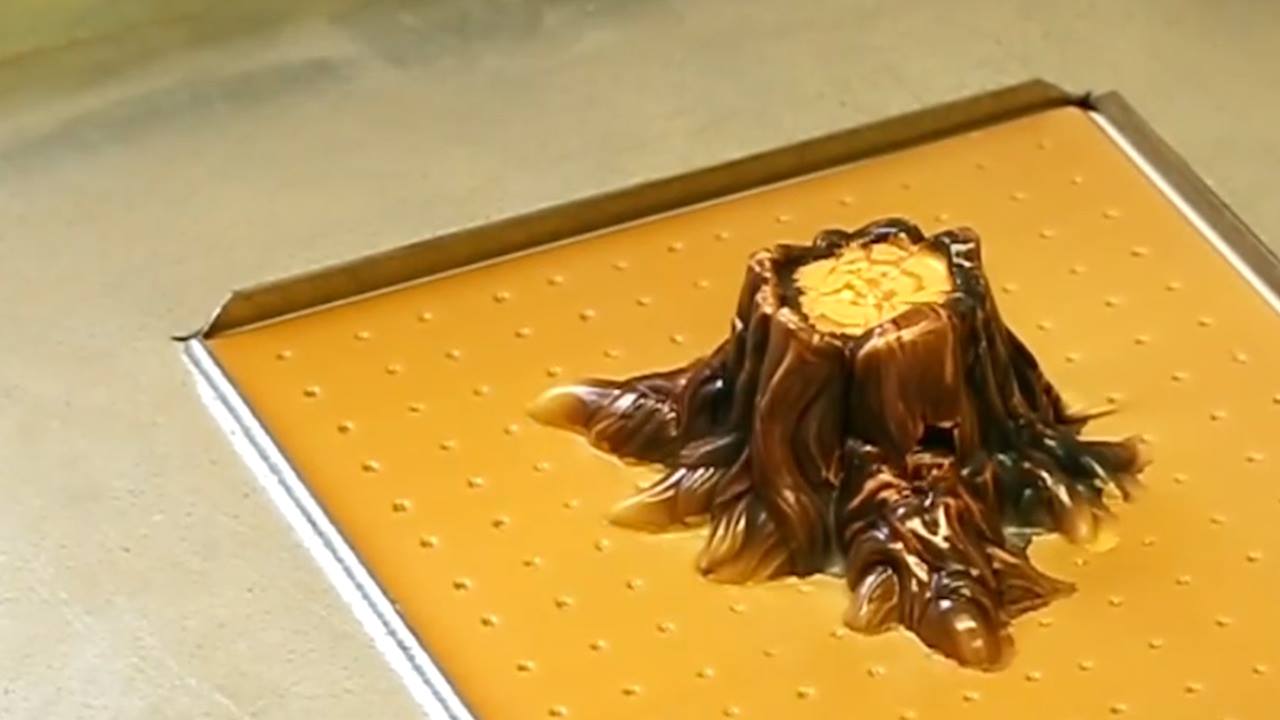

New Disney Technology Takes 3D-Printing Up A Notch

Posted by Lily Graca in category: 3D printing

Aug 2, 2016

Saudi Arabia plans to 3D print 1.5 million houses with WinSun’s construction 3D printing tech

Posted by Karen Hurst in categories: 3D printing, engineering, habitats

WOW — now that’s an engineering feat.

While Dubai is keen to become a 3D printing world leader with their Dubai 3D Printing Strategy, they are by no means the only Middle Eastern nation to look into this technology. Last week a delegation of Chinese WinSun officials traveled to Riyadh, the capital of the Kingdom of Saudi Arabia, to discuss construction 3D printing. Among others, the Chinese construction 3D printing pioneers were invited to 3D print up to 1.5 million housing units over the next five years.

Aug 2, 2016

Dubai to become an international 3D printing hub

Posted by Karen Hurst in categories: 3D printing, computing

Impressive.

3D printing services will grow from $2.5bn in 2013 to $16.2bn in 2018, according to Canalys Tags: 3D printing, Cloud computing.

Aug 2, 2016

Big Data’s Role in 3D Printing

Posted by Karen Hurst in categories: 3D printing, biotech/medical, business, information science

Big Data and 3D.

3D printing remains one of those technological areas that holds a great amount of fascination. What began as a type of niche market has expanded rapidly in the past few years to encompass nearly every industry out there, from the medical field to manufacturing.

The outlook is a positive one in terms of 3D printing’s future, with Gartner predicting the amount of spending on 3D printers to exceed more than $13 billion in 2018. While 3D printing has always held a lot of promise, one of the factors truly taking the concept to the next level is big data.

Aug 1, 2016

Your Dinner Is Ready To Be 3D Printed

Posted by Karen Hurst in categories: 3D printing, food

Could we see a day when 3D Printers replace convection ovens and microwaves in the kitchen?

Over the last few decades, a new wave of science has been infused into the world of food in the form of molecular gastronomy. By definition, food preparation and cooking involve physical and chemical changes, and molecular gastronomy simply uses scientific principles to take food in new technical and even artistic directions.